5 Factors To Influence Antibody Production | How To Prevent?

Apr 12th 2022

When it concerns custom antibodies in response to modern medical research, various factors can determine the use of advanced therapeutics in in-vitro assays. Meanwhile, antibody production and peptide synthesis are in-demand and time-consuming processes, so choosing a suitable supplier is essential.

Importance of Quality Antibodies

Research suggests there is no underlying doubt that specific antibodies are special tools for the clinic and analysis. They are further utilized to identify and alleviate illnesses, to perform bioanalysis of biological systems and drugs. In addition to the development process, they are crucial during the clinical development of therapeutics and are primarily helpful as therapeutics themselves. But, it is pretty acknowledged that clinical antibodies might fail to distribute on their intended outcome if they have not been flawlessly produced.

The problem with antibodies is that they are complex in their generation. Besides, various factors can affect every stage of the production procedure. Such issues are then discussed thoroughly. It is evident that without due diligence of steps involved, the produced antigen might not satisfy the demands and is likely to produce poorly on multiple characteristics. This fails to deliver reproducible and standard data with correlated regulatory, financial, commercial, and scientific repercussions.

Image source: https://unsplash.com/photos/G66K_ERZRhM

Luckily, if you work with contract research-based firms or scholars, they can prevent such risks. According to a study, some labs are operated by skilled professionals who have been running tests with antigens for an extended period. They understand the requirement for optimized protocols and concise consideration of every factor that could observe the product’s final quality.

Clients looking for an optimal antibody production service value the potential of producing consistent antibodies at workable timescales. Several forms of research have also indicated that services like gene synthesis can also make a considerable difference in the cell line antibody specificity.

Polyclonal & Monoclonal Antibody

Polyclonal and monoclonal antibodies are a significant part of the most effective selling therapeutics. A scholar explains how such antibodies can differ. He says that immunoglobulins are Y-shaped molecules secreted by B cells to neutralize or eliminate antigens. It is the medium of developing such antibodies that can classify them as monoclonal or polyclonal. Moreover, it implies that mAbs can identify only a single antigen’s epitope. In contrast, pAbs would have a more considerable affinity to a specific antigen because of the identification of various epitopes.

The advantage of utilizing monoclonal over polyclonal antibodies in studies is that they are relatively more homogenous and comprise a more significant batch-to-batch stability. However, on the other hand, monoclonal antibody sequencing needs other processes and skills. Such a result can lead to additional time and costs to produce batches.

As a result, whether a monoclonal or polyclonal antibody is required in the procedure relies on the application, timescales of a specific project, and whether cell lines already exist. One of the key benefits of working with trusted providers while making such decisions is that users can capitalize on the experience and specialists to maneuver their choices. To alleviate the seriousness of the virus, several investigators worldwide have stated what antigens such a disease can produce. Regardless of what the antibodies inform, a researcher can utilize them to promote rapid vaccine production.

While researchers were rooting for several forms of vaccines, many experiments led to immune responses in participants that showed different relativity between every human. As a result, it is vital to acknowledge the factors that could determine how industrial antigens are developed to evaluate the possibility of further treatments. Hybridoma sequencing is the antibody protein sequencing of the cDNA, which encodes the variable light (VL) and variable heavy (VH) domains of your hybridoma cell lines.

Natural antibody production

Image source: https://unsplash.com/photos/gKUC4TMhOiY

Natural antigens are the foremost line of defense that newborn organisms have against adverse pathogens. In addition to adaptive antibodies, natural ones can increase germ-free conditions (specific to particular antibodies). Post-antibody-injection, one needs to know that natural antigens developed in participants comprise immunoglobulin M (IgM), IgA, which includes its isotypes IgA2 and IgA1, and IgG and specific isotypes.

Recurring antibodies are relatively more commonly developed via lymphocytes and marginal B cell zones where human beings are still in the pre-fetal process. Some influential properties of such antigens comprise polyreactivity, autoreactivity, significant avidity levels, and standard affinity tags. Even though natural antigens dominate 1% of the immunoglobulins available in the blood, with their figures depreciating, they can serve essential roles in preventing multiple illnesses like atherosclerotic plaque formation, autoimmune diseases, inflammation, and specific cancer types.

Adaptive antibody production

If the specific antigen is granted to innate immune systems and antibodies can’t control certain infection forms, the immune response gets activated. In addition to the adaptive nature of the production process, there are two primary immune responses, including the cell-mediated and humoral immune responses.

On the other hand, the cell-mediated response can be achieved through T cells, a humoral immune response. Besides, it ultimately depends on particular activities of B cells and adaptive antigens.

When it concerns natural antibodies developed before foreign pathogen exposure, one could only produce the latter after an antibody interacts with B-cell receptors of B2 lymphocytes. Furthermore, the binding process of an antigen to another B cell can initiate the discharge of selected cytokines that leads to rapid proliferation. While the B cells still reproduce, researchers can secrete antibodies with similar antigen patterns initially located on the BCR. What’s more? One can effortlessly produce immune responses with direct exposure to selected pathogens.

Factors influencing antibody production

Due to an antibody’s structure or format, its state of susceptibility and aggregation to proteases can significantly affect its stability. However, some vital factors can affect the process and enable optimization of antibody stability.

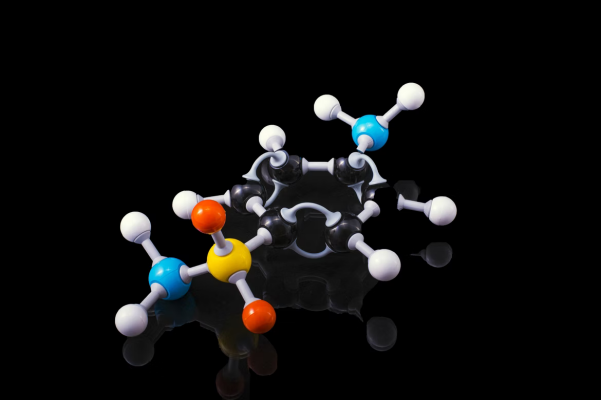

Issues in expression and production

One of the researchers examined the custom protein expression influence of vector designs and found that the expression levels from CHO cells can be qualified as stable. The collation between vector design efficiency states that dual promoter systems provide a significant level of stability and expression while determining the highest antibody productivity. Whether protein expression services or the protein production service, antibody sequencing services, or protein expression and purification services, a reputed scholar can tackle the challenge swiftly.

Image source: https://unsplash.com/photos/kCrrUx7US04

The MBP or maltose-binding protein is one of the stable monomers that does not induce aggression when infused as tags on recombinant protein expressions. Another researcher investigated the utilization of MBP tags and found that they considerably enhanced the in vitro refolding yield compared to alternative hexahistidine or other tags. More interestingly, a delicate solubilization process and in vitro refolding methods can prove effective in recovering soluble tag-free scFv.

When it concerns the mild solubilization procedures, they could have a potential for economical and efficient recombinant production with specific optimization. That’s because it does not need any fusion tags. On the other hand, the E. coli expression system can enable quick expression and subsequent large-scale manufacturing of recombinant antigens.

Proteolysis/fragmentation

Antibody proteolysis can materialize in the plant host and mammalian cells. Such a procedure is undesirable as it can impact the yield and accommodate product quality. Therefore, a potent IgG4 mAb-X is used to express seamlessly primarily around the hinge regions.

While working with mouse IgG1κ monoclonal antibodies, investigators expressed Nicotiana tabacum and noted the availability of minor fragments clubbed with whole proteins. Such proteins resulted from proteolytic cleavages. Further investigations were made, and an insufficient number of sites were vulnerable to proteolysis, affecting antibody production.

Aggregation

Antigens tend to aggregate under the production procedure because of multiple chemical interactions that can administer the structure. Generally, two forms of aggregation are present: non-native and native. Comprehensive aggregation can result in visible particle formation and antibody precipitation. Furthermore, aggregation is one of the primary factors affecting stability during antibody production procedures, storage, and delivery. Here, antibody aggregation can also lead to a low yield from host cells, further affecting biological formations. Besides, this could also enhance immunogenic responses. As a result, researchers work effortlessly to avoid such severe effects.

Effects of antibody structure and formats

The entire mAbs contain variable and constant domains of heavy and light chains. Regardless of the real throughput, the variables are relatively more stable than any other fragment, which are much meager to administer or even determine. In addition to the antibody structure and format, glycans can aid protein foldings and stabilize the specific system while protecting against aggregation and proteolysis.

Image source: https://unsplash.com/photos/RflgrtzU3Cw

Glycosylation is another post-translational attachment of glycans structures. However, it is challenging to characterize the possibility of modification, aggregation, and degeneration of glycosylated monoclonal antibodies during storage, application, and manufacture because of their significant size and number of active groups. Talking about the thermodynamic stability of scFv, it can vary considerably. Moreover, most monoclonal antibodies-specific scFv comprise poor to moderate steadiness without protein engineering. When a researcher combines this with patent problems, scFv has experienced a limited application.

Grafting of CDRs to improve antibody strength

In most cases, the metamorphosis of scFv to scAb, IgG, or Fab might improve steadiness. For instance, one researcher, Quintero Honeggar, found a significant improvement in stability after converting the scFv to Fab antigen formats. He quoted, ‘as the thermodynamic stabilities of antigen domains vary broadly, the engineering process is limited to the number of mutations a domain experiences. Moreover, such a process can further improve antibody stability while accommodating affinity and specificity.

Interestingly, the tiniest intact antibody-binding fragments - single domain antibodies showed affinity and specificity similar to Fab and scFv. However, higher solubility and steadiness of their straightforward structure enable a robust refolding efficiency.

Crafting highly prudent cell lines needs a specific level of care that can begin with cell line production. Several forms of research understand the difficulties clients face throughout the procedure. Here, they recently stated some traditional production issues and provided solutions for making sure antibody production does not get compromised and that reliable and consistent throughput is achieved. As a result, an individual needs to learn tips on avoiding low-yielding production.

Tip 1: Maintain sample integrity

One of the fundamental, preventable problems with antibody production deals with cell storage contamination and temperatures. Inadequate sample storage during shipping and in cells can lead to fluctuations in temperature, stressing the cell lines. Consequently, stressed cells may immensely hinder the process of antibody production, which requires comprehensive efforts to achieve cell lines back to efficient production levels. Stringent accommodation of samples during the shipment step can ensure optimal temperatures and maintain procedure and facility success.

Contamination with adventitious agents has become quite a problem over the last three decades. However, it remains an issue. As already discussed, contamination has always been a primary concern for investigators. To prevent its potential, one can adhere to well-documented lab methods, tested supplements and media, and suitable distribution of equipment and cells.

Tip 2: Document for higher returns

With current mergers and company buyouts, clones are likely to be sold, passed, or inherited but might lack a whole custody chain. In addition, an operational cell line may, hence, have significant commercial potential and promise. Provided that biological operations do not always perform as planned or perceived and might have unpredictable production behavior, organizations need to ensure they’re recurrently capturing the data and essential documents and verifying that their selected clones meet experiment expectations. Maintaining and keeping all records can also assist in avoiding downstream challenges during antibody production and help preserve timelines like never before.

Tip 3: Promote downstream production with patience

Image source: https://unsplash.com/photos/8yS04veb1TQ

Most cell lines are at first produced swiftly to answer research questions for small projects. Over time, your cell lines may become valuable and get evaluated for their commercial potency. Meanwhile, if you create cells rapidly, ensure optimal antibody production, or you might compromise their yield. Cells would need abundant effort and time to perform impeccably, or the user will be left with selected cell lines, increasing their production budgets.

Tip 4: Assess the potential development partner’s attributes

When choosing partners to assist the custom antibody development, it is essential to acknowledge their history, capacity, and flexibility. An organization with a proven track record can have suitable quality SOPs and assurance controls. Request for documentation that can demonstrate their potential to reproduce procedures that can ensure product consistency.

Conclusion

In the modern age of biosciences, custom antibody production will always face challenges. However, with proactive strategies to prevent common pitfalls, a researcher can enhance their chances for success. Based on the antibody’s ultimate application, you can begin with a non-partisan approach and consider whether monoclonal or polyclonal antibodies are ideal for your selected application.